AI-powered drone platform for automated crop disease detection and pesticide application

/The Need

Virus Shield Biosciences, a UK-based agricultural technology company, recognized that traditional crop disease management relied on manual field inspections, scheduled pesticide applications, and reactive treatment approaches that resulted in excessive pesticide use, delayed disease detection, and high labor costs. Farmers faced challenges in detecting crop diseases early before significant damage occurred, applying pesticides precisely only where needed rather than blanket spraying entire fields, monitoring large agricultural areas efficiently without excessive manual labor, and optimizing treatment timing to maximize effectiveness while minimizing chemical use.

The company needed a smart drone platform that could automate crop disease detection using machine learning and real-time video analytics, provide GPS-based spray automation for precision pesticide application, and deliver cost and labor reduction through optimized treatment and automated large-scale farm operations. With the goal of achieving 70% pesticide waste reduction and saving 5,000+ hours of manual operation time, Virus Shield Biosciences required a comprehensive AI-powered precision agriculture solution that would transform crop protection from reactive, labor-intensive, chemical-heavy practices to proactive, automated, data-driven disease management.

The Solution

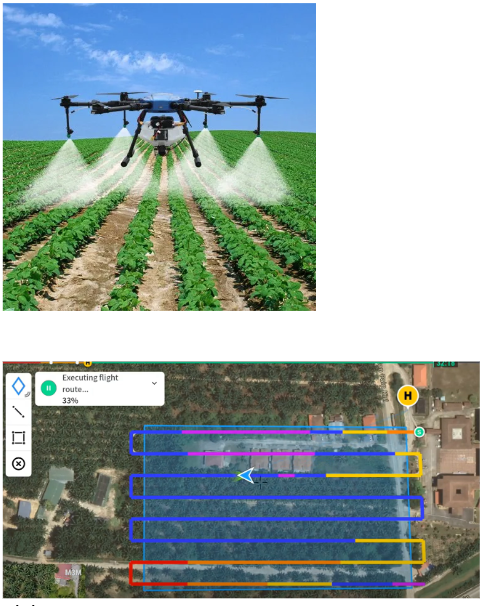

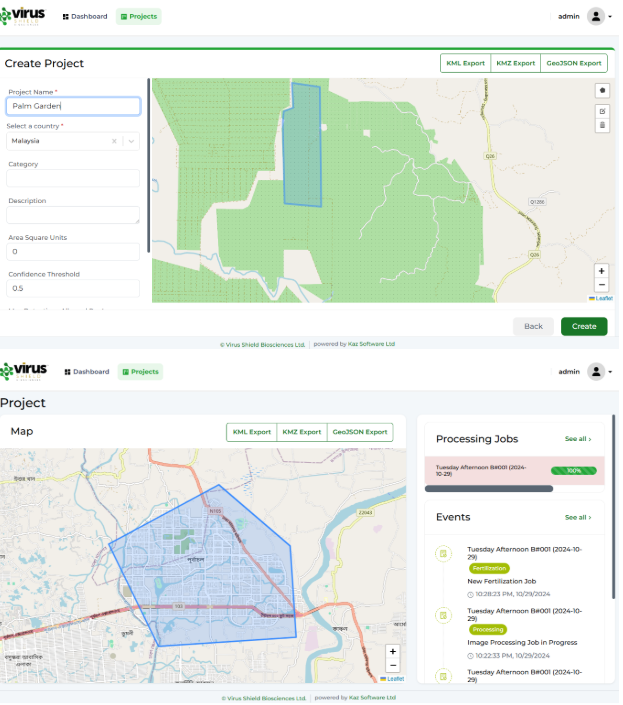

We partnered with UK-based Virus Shield Biosciences to develop a smart drone platform that revolutionized crop disease management through AI-powered automation and precision agriculture, delivering substantial environmental and economic benefits.The Real-Time Disease Detection capability employs machine learning models that detect crop issues via live drone video using CVAT (Computer Vision Annotation Tool) and Detectron2. As drones fly over fields capturing high-resolution video, the AI analyzes footage in real-time identifying disease symptoms including discoloration, wilting, spots, or abnormal growth patterns, classifying disease types and severity levels, pinpointing exact locations of infected areas using GPS coordinates, and generating immediate alerts for farmers to review. The ML models were trained on thousands of annotated crop disease images, learning to distinguish healthy plants from those affected by various pathogens, pests, or nutrient deficiencies. This real-time detection enables early intervention when diseases are most treatable, preventing spread to healthy crops and minimizing yield loss.

The GPS-Based Spray Automation feature enables software to issue precision flight and spray instructions via DJI SDK (Software Development Kit). Once diseases are detected, the system automatically calculates optimal treatment plans determining which specific areas require pesticide application, calculating precise pesticide quantities needed based on infection severity and area, generating flight paths for drones to cover affected zones efficiently, and programming spray patterns to target diseased plants while avoiding healthy areas. The integration with DJI drones enables automated execution where drones follow programmed routes, activate sprayers only over infected areas, adjust spray rates based on disease severity, and return for refills as needed—all with minimal human intervention. This precision application dramatically reduces pesticide waste compared to traditional blanket spraying.The Global-Scale Agri Use demonstrates successful adaptation to fruit orchards and global crop types. While initially developed for specific crops, the platform's flexible ML architecture enables training models for diverse agricultural contexts including fruit orchards detecting fungal infections, pest damage, or ripeness issues, grain crops identifying rust, blight, or pest infestations, vegetable farms monitoring disease and pest pressure, and specialty crops adapting to unique disease profiles.

This scalability enables Virus Shield Biosciences to serve farmers globally regardless of what they grow, with ML models continuously improving through exposure to new crop types and disease patterns.The Cost & Labor Reduction benefits come from optimized pesticide use and automated large-scale farm operations. The platform reduces costs by minimizing pesticide waste through precision application, decreasing labor requirements for manual field scouting, preventing yield loss through early disease detection, and reducing equipment wear from unnecessary spraying. Labor is saved by automating disease monitoring across vast acreage, eliminating manual spray calibration and application, and reducing time spent on treatment planning and execution. The automated operations enable farmers to manage larger areas with fewer staff while achieving better disease control outcomes. The measurable impact demonstrates the platform's value: achieving 70% pesticide waste reduction through precision targeting, and saving 5,000+ hours of manual operation time by automating disease detection and treatment application.

The Challenge

The primary challenge was developing machine learning models that could accurately detect diverse crop diseases from drone video in real-world agricultural conditions with varying lighting, weather, crop varieties, and disease manifestations. Training ML models required massive datasets of annotated images showing healthy and diseased crops across growth stages, using CVAT for efficient annotation workflows. The models needed to distinguish diseases from similar-looking conditions (nutrient deficiencies, drought stress, mechanical damage) and operate reliably despite video quality variations, motion blur, or partial plant occlusion.Implementing real-time video analytics on resource-constrained drone platforms required optimizing ML inference for edge computing. Processing high-resolution video streams in real-time while flying demanded efficient model architectures, careful compute resource management, and robust software ensuring stable operation despite connectivity issues or hardware limitations.

Integrating GPS-based spray automation with DJI drones via their SDK required understanding drone flight control APIs, spray system interfaces, and safety protocols. The software needed to generate flight paths that covered diseased areas efficiently while respecting no-fly zones, obstacles, and wind conditions, program spray patterns that delivered precise pesticide quantities, and handle error conditions like low battery or mechanical issues gracefully.Adapting the platform for global-scale agricultural use across diverse crop types required flexible ML pipelines supporting rapid model training for new crops, transfer learning leveraging knowledge from existing models, and continuous improvement as the system encountered new disease patterns. The platform needed to accommodate different farming practices, regulatory requirements, and operational contexts across global markets.Achieving 70% pesticide waste reduction while maintaining effective disease control required proving that precision application was as effective as traditional blanket spraying—requiring field trials, agricultural science expertise, and farmer education demonstrating that targeted treatment worked better than over-application.

The Partnership

Our collaboration with Virus Shield Biosciences was driven by a shared vision of transforming agriculture through AI and precision technology while reducing environmental impact and improving farmer economics. We worked closely with their agricultural scientists, drone specialists, and farming partners to design a platform genuinely serving real-world crop protection needs.The partnership involved extensive field testing to understand disease detection requirements, validate ML model accuracy, optimize spray automation, and demonstrate economic and environmental benefits to farmers. We collaborated with agricultural experts to build training datasets, validate disease classifications, and ensure treatment recommendations aligned with agronomic best practices. We built the complete technology stack using Python for ML model development with Detectron2 for object detection and CVAT for annotation workflows,

Node.js and React for the web platform enabling farmers to review disease alerts and manage drone operations, DJI SDK integration for automated drone flight control and spray operations, AWS Lambda for serverless compute handling video processing and ML inference, and GIS tools like Google Maps API for spatial visualization and flight path planning. The platform also integrates with MongoDB for data management storing crop health records, treatment history, and operational analytics.We delivered full-cycle development from ML model training through platform deployment, provided ongoing model improvement as new crop types and disease patterns were encountered, and supported Virus Shield Biosciences' expansion into global markets with platform adaptations for different agricultural contexts. The measurable success—achieving 70% pesticide waste reduction and saving 5,000+ hours of manual operation time—demonstrates how this collaborative approach created a platform that genuinely advances sustainable agriculture while improving farmer profitability through AI-powered precision crop protection.

The Tech Stack

We built the platform using Python with Detectron2 and CVAT for ML-powered disease detection, Node.js and React for the web platform, DJI SDK for drone control, AWS Lambda for serverless processing, GIS tools like Google Maps API for spatial planning, and MongoDB for data management. Python provides the foundation for machine learning with Detectron2 delivering state-of-the-art object detection for identifying diseased plants in drone video, and CVAT streamlining annotation workflows for building training datasets. Node.js powers the backend API handling video uploads, ML inference requests, spray planning, and drone command generation. React delivers the farmer-facing web interface for reviewing disease alerts, managing drone fleets, and accessing crop health analytics. DJI SDK integration enables automated drone operations including programmed flight paths, precision spray control, and real-time telemetry.

AWS Lambda provides serverless compute for scalable ML inference processing video streams without maintaining dedicated servers. Google Maps API and GIS tools enable spatial visualization of disease hotspots and generation of GPS-based flight paths optimizing coverage and spray efficiency. MongoDB stores crop health records, treatment history, ML model outputs, and operational data enabling continuous platform improvement. The integrated platform delivers real-time disease detection via ML models analyzing live drone video, GPS-based spray automation issuing precision flight and spray instructions, global-scale agricultural adaptability across diverse crop types, and cost and labor reduction through optimized pesticide use and automated operations—achieving 70% pesticide waste reduction and saving 5,000+ hours of manual operation time for farmers globally.